Neoceram’s proprietary trademarks represent the cornerstone of our advanced material and system innovations. Each brand embodies a breakthrough in performance: from ultra-pure ceramics engineered for pharmaceutical excellence to modular designs that simplify operations and maximize flexibility. These distinctive solutions reflect Neoceram’s commitment to raising industry standards and delivering the next generation of reliability, safety, and adaptability to our global partners.

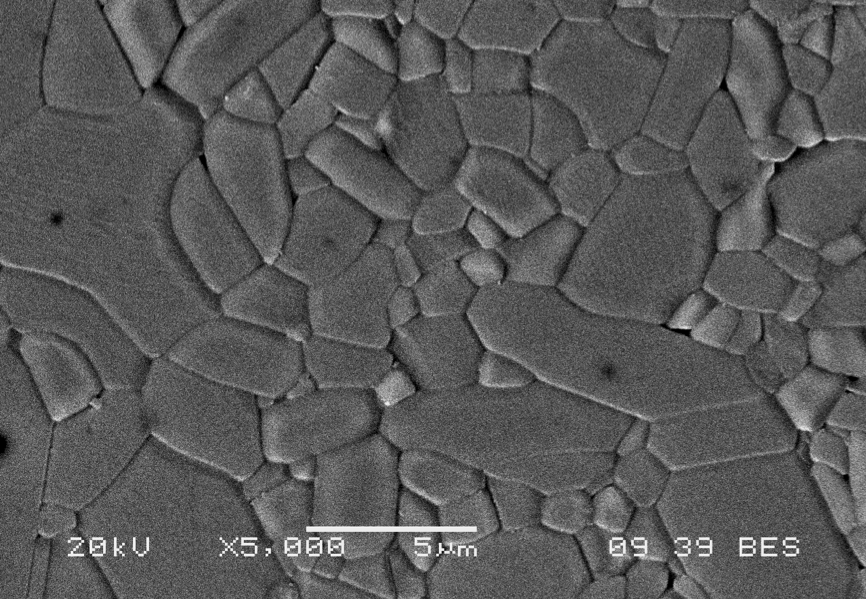

Pharmalox® is a high purity alumina ceramic (>99.7% Al2O3) specially designed for our products.

The high purity of this material results in very clean grain boundaries which contribute to its excellent corrosion resistance in the presence of both acid and alkali-based cleaning solutions e.g. NaOH and HCl.

Pharmalox® is inert, non-cytotoxic and does not release particles. It is easy to clean due to the low porosity. It has high wear resistance, a low friction coefficient and accepts very smooth surface finishes.

Pharmalox® complies with directive 80/500/EEC amended and FDA regulation

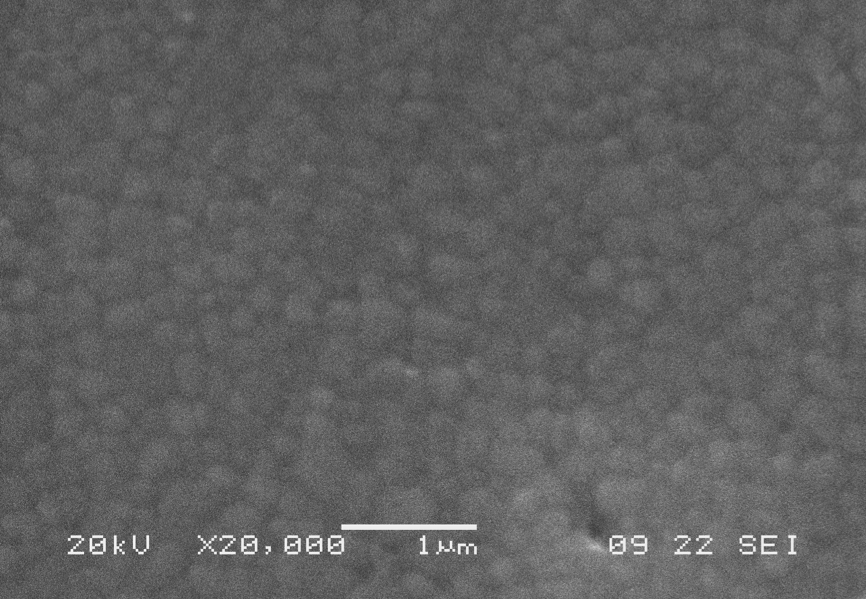

Pharmazirc® is a Yttria partially-stabilized zirconia ceramic specially designed for our products.

Its carefully controlled chemistry and microstructure imparts excellent resistance to corrosion by both acid and alkali cleaning solutions and to the hydro-thermal destabilization that happens with other zirconia ceramics during steam sterilization.

This material is also non-cytotoxic and does not release particles. It is easy to clean due to the low porosity. It has high wear resistance, a low friction coefficient and accepts highly smooth surface finishing as a result of its very fine grain size and low porosity.

Pharmazirc® complies with Directive 80/500/EEC amended and FDA regulation

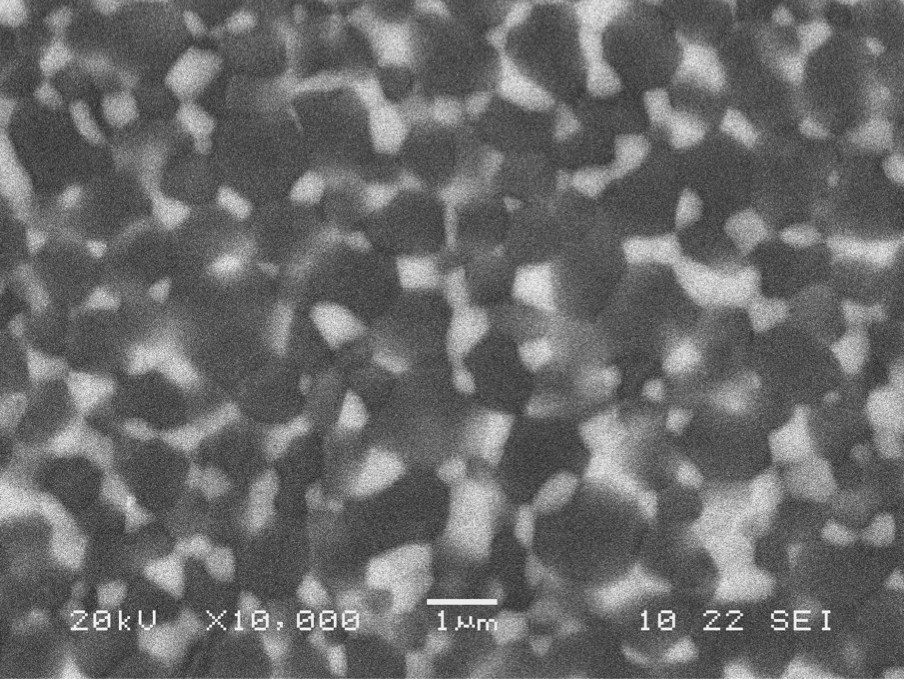

Thermazyl® is a zirconia toughened alumina ceramic specially designed for our products.

Its carefully controlled chemistry and microstructure imparts excellent resistance to corrosion by both acid and alkali cleaning solutions and to the hydro-thermal destabilization that happens with zirconia ceramics during steam sterilization. This material has been especially designed for application requiring good thermal shock resistance.

This material is also non-cytotoxic and does not release particles. It is easy to clean due to the low porosity. It has high wear resistance, a low friction coefficient and accepts highly smooth surface finishing as a result of its very fine grain size and low porosity.

Thermazyl® is X-Ray detectable (smallest detectable size as low as 0,8 mm) and complies with Directive 80/500/EEC amended and FDA regulation

Neoceram Pumps: Fully Interchangeable Male Components

The X-change® system ensures dimensional precision in machining pistons, valves, and cylinders, making male components fully interchangeable—not just within the same batch, but also across batches with identical clearance.

With 20+ years in the pharmaceutical industry, Neoceram identified matching errors as a major cause of leakage, seizing, and pump jamming.

With X-change®, pistons and cylinders are exactly the same size, eliminating seizing risks. If a piston breaks, a single spare fits all cylinders, reducing stock and costs

BENEFITS

We customize products and solutions to deliver precision, reliability, consistency and innovative design