APPLICATIONS

FOOD AND BEVERAGE

Hygiene, precision, and durability are vital in the food & beverage sector, and our ceramic piston pumps are designed to meet these demands. Neoceram has expertise in a wide range of food applications.

With no dynamic seals, our pumps ensure a hygienic design that minimizes contamination risks and simplifies cleaning. Neoceram Food solutions are ideal for filling various products, including: Yoghurts with fruits • Cheese spreads • Molten cheese • Sauces • Soups • Jams & marmalades • Milk • Ice cream • Chocolate, offering exceptional product cut and precise dosage.

Our solutions also provide strong resistance to particulates and are available in CSIP-compliant designs, ensuring that they meet the industry’s strict safety and quality standards.

Click each section to view related components. Each entry is a direct link to product details

COMPONENTS

CERAMIC ROTARY VALVES – Coming Soon

PUMPS – Coming Soon

NOZZLES – Coming Soon

ENGINEERING & SERVICES

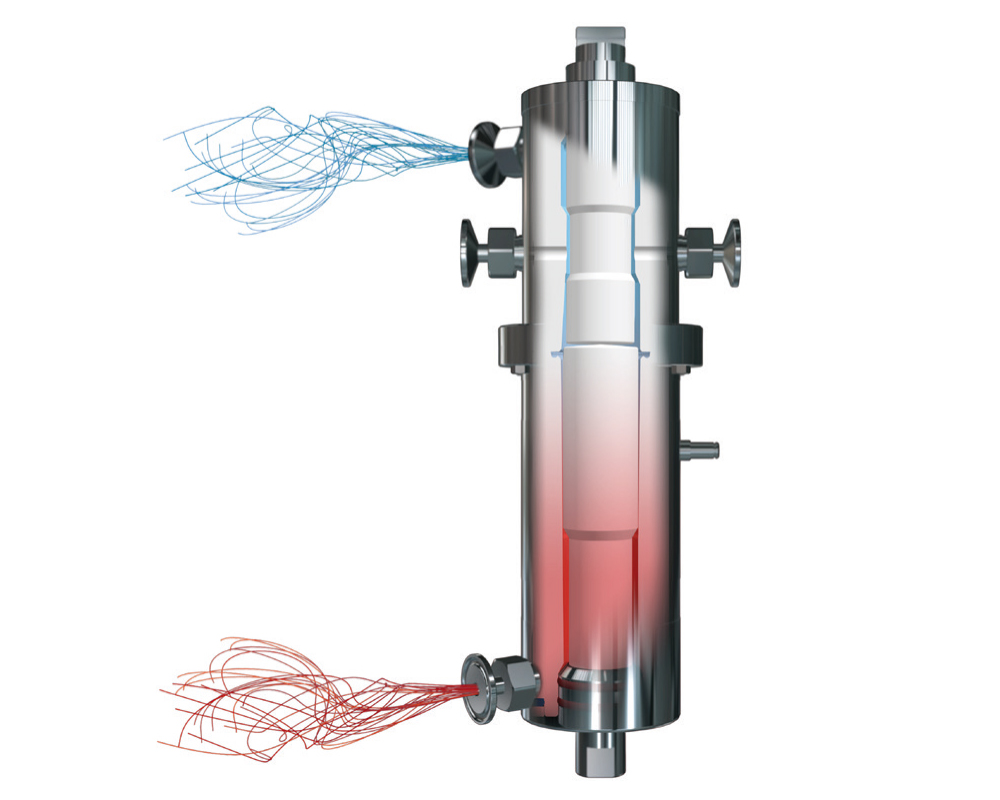

THERMAZYL® – OUR CERAMIC COMPOUND FOR FOOD APPLICATIONS

Neoceram’s proprietary ceramics, Pharmazirc® and Pharmalox®, deliver exceptional sterile filling performance, offering high resistance to sterilization, mechanical stress, and superior cleanability.

Our latest innovation, Thermazyl®, combines the advantages of Pharmazirc® and Pharmalox®, with superior resistance to thermal shocks caused by rapid temperature changes between hot steam and cold water used in cleaning and sterilization (CIP and SIP processes). Thermazyl® is specifically formulated for the food industry and offers:

- Clean and aseptic filling with fast sterilization cycles

- High-temperature dosing (up to 100°C)

- Dynamic CIP (no gaskets, no seizing)

Neoceram Thermazyl® is also X-ray detectable, ensuring enhanced safety and compliance.

CLEAN, PRECISE, AND EFFICIENT: The Neoceram Edge in Food Dosing Technology

NO CONTAMINATION OF THE DOSED PRODUCT

- Superior wear resistance

- High corrosion resistance

- Suitable for daily cleaning/sterilization cycles

- Self-sealing solutions (NO SEALS)

- Dry-run operation (NO LUBRICANTS required)

- Hygienic design

EFFECTIVE DOSING FOR CHALLENGING PRODUCTS

- NO DRIPPING

- NO SEIZING due to solid inclusions

- High accuracy

- Superior performance for fibrous food

REDUCED MAINTENANCE COST AND TIME

- Improved productivity

- Reduced errors

- Enhanced risk mitigation

A BENCHMARK FOR PRECISION DOSING

Neoceram’s innovative ceramic solutions set the benchmark for precision dosing in the food industry, ensuring reliability, efficiency, and compliance with the highest food safety standards.

PRECISE, HYGENIC SOLUTIONS FOR FOOD DOSAGE