APPLICATIONS

PHARMA

Our precision dosing solutions are engineered to meet the stringent demands of the pharmaceutical industry, where accuracy and surface finish are crucial.

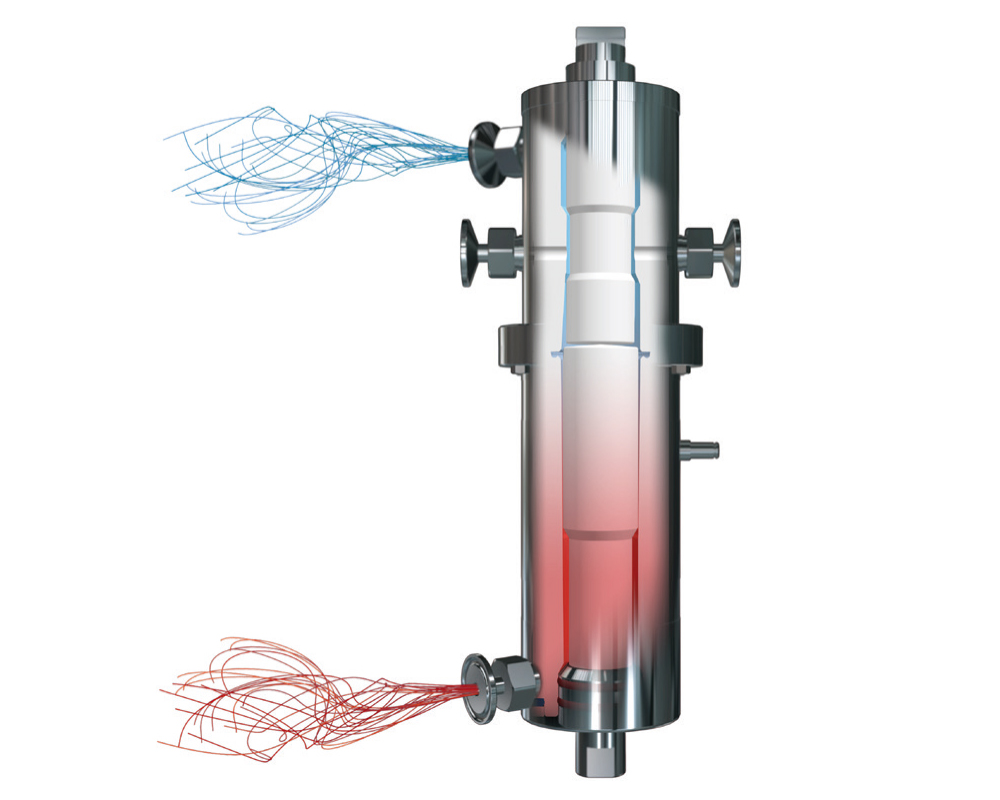

Our ceramic piston pumps deliver unparalleled precision in applications such as pharmaceutical manufacturing, biologics, and diagnostics, ensuring consistent dosing and minimizing the risk of contamination.

The absence of dynamic seals, combined with our advanced designs, enhances cleanability, simplifies maintenance, and boosts process efficiency in sterile environments.

With exceptional resistance to aggressive chemicals and sterilization processes, our solutions help meet regulatory requirements and extend equipment lifespan

Click each section to view related components. Each entry is a direct link to product details

COMPONENTS

DOSING SYSTEMS

ENGINEERED FOR EXCELLENCE: Why leading brands trust NEOCERAM

COMPATIBILITY WITH DOSED PRODUCTS

Neoceram’s proprietary materials; Pharmazirc® and Pharmalox® are non-cytotoxic materials known for their extremely high density, chemical inertness, and superior resistance to wear and chemicals. This makes them ideal for use with products that are sensitive to stainless steel or reactive to other contact surfaces.

NO LUBRICATION REQUIRED

Neoceram pumps can operate dry for extended periods without seizing. This eliminates the need for lubricants, reducing the risk of product contamination during the filling process.

EFFICIENCY AND EASE OF USE

The high precision and small clearances between components allow for quick and simple setup at the start of each batch. Once in operation, the pumps can run at high speeds with low operational costs and minimal maintenance.

EXTENDED SERVICE LIFE

Made entirely of monolithic ceramic with no surface coatings, Neoceram pumps are designed to resist shock during handling and assembly. When properly used, they offer a service life of 5 to 10 years, maintaining consistent dosing precision without maintenance.

SETTING THE STANDARD

Neoceram solutions set the standard for precision dosing in the pharmaceutical industry, ensuring reliability, efficiency, and compliance with the highest industry standards.

ADVANCED CERAMIC TECHNOLOGY FOR FLUID DISPENSING

FOOD AND BEVERAGE

Hygiene, precision, and durability are vital in the food & beverage sector, and our ceramic piston pumps are designed to meet these demands. Neoceram has expertise in a wide range of food applications.

With no dynamic seals, our pumps ensure a hygienic design that minimizes contamination risks and simplifies cleaning. Neoceram Food solutions are ideal for filling various products, including: Yoghurts with fruits • Cheese spreads • Molten cheese • Sauces • Soups • Jams & marmalades • Milk • Ice cream • Chocolate, offering exceptional product cut and precise dosage.

Our solutions also provide strong resistance to particulates and are available in CSIP-compliant designs, ensuring that they meet the industry’s strict safety and quality standards.

NEOCERAM Food is proud to be an Orthodox Union-certified company for Kosher food filling and complies with CEE 1935/2004, as well as Japan and California regulations.

Click each section to view related components. Each entry is a direct link to product details

COMPONENTS

THERMAZYL® – OUR CERAMIC COMPOUND FOR FOOD APPLICATIONS

Neoceram’s proprietary ceramics, Pharmazirc® and Pharmalox®, deliver exceptional sterile filling performance, offering high resistance to sterilization, mechanical stress, and superior cleanability.

Our latest innovation, Thermazyl®, combines the advantages of Pharmazirc® and Pharmalox®, with superior resistance to thermal shocks caused by rapid temperature changes between hot steam and cold water used in cleaning and sterilization (CIP and SIP processes). Thermazyl® is specifically formulated for the food industry and offers:

- Clean and aseptic filling with fast sterilization cycles

- High-temperature dosing (up to 100°C)

- Dynamic CIP (no gaskets, no seizing)

Neoceram Thermazyl® is also X-ray detectable, ensuring enhanced safety and compliance.

CLEAN, PRECISE, AND EFFICIENT: The Neoceram Edge in Food Dosing Technology

NO CONTAMINATION OF THE DOSED PRODUCT

- Superior wear resistance

- High corrosion resistance

- Suitable for daily cleaning/sterilization cycles

- Self-sealing solutions (NO SEALS)

- Dry-run operation (NO LUBRICANTS required)

- Hygienic design

EFFECTIVE DOSING FOR CHALLENGING PRODUCTS

- NO DRIPPING

- NO SEIZING due to solid inclusions

- High accuracy

- Superior performance for fibrous food

REDUCED MAINTENANCE COST AND TIME

- Improved productivity

- Reduced errors

- Enhanced risk mitigation

A BENCHMARK FOR PRECISION DOSING

Neoceram’s innovative ceramic solutions set the benchmark for precision dosing in the food industry, ensuring reliability, efficiency, and compliance with the highest food safety standards.

PRECISE, HYGENIC SOLUTIONS FOR FOOD DOSAGE

COSMETICS

For the Cosmetics industry, our solutions are tailored to handle complex and abrasive products like exfoliating scrubs, lotions, and thick creams.

The hard particulate resistance of our ceramic piston pumps allows them to maintain smooth, consistent dosing even with challenging materials. Whether you’re producing high-viscosity formulations or delicate skincare products, our pumps ensure precision and efficiency.

Additionally, the improved cleanability of our systems helps maintain hygienic standards, reducing product waste and ensuring consistent quality batch after batch

Expertise in a Wide Range of Cosmetic Applications Neoceram Cosmetics has extensive experience in dosing various cosmetic and personal care products, including: Silky body lotions and moisturizers • Luxurious shower and bath gels • High-viscosity creams and butters • UV-protective sunscreens • Lightweight and nourishing serums • Essential and therapeutic body oils • Roll-on and spray deodorants • Exfoliating scrubs with microparticles • Liquid soaps and hand sanitizers

Click each section to view related components. Each entry is a direct link to product details

ENGINEERED FOR BEAUTY: High-Precision Ceramic Dosing

- High-purity ceramic materials prevent contamination and preserve product integrity.

- Superior chemical resistance ensures compatibility with a wide range of cosmetic formulations.

- No seals or lubricants required, minimizing maintenance and reducing downtime.

- Precision dosing technology guarantees accurate and consistent filling, even for complex viscosities.

- Extended lifespan and low maintenance, offering cost-effective, long-term performance.

SUPERIOR SOLUTIONS FOR COSMETIC DOSAGE

HOME CARE

In the fast-paced world of home care products, speed and corrosion resistance are critical to ensuring efficient and reliable production.

Our pumps are designed to handle aggressive chemicals found in cleaning products, while maintaining their integrity over time. From liquid detergents to surface cleaners, our dosing solutions provide high-speed, accurate dispensing, significantly reducing maintenance downtime.

The corrosion-resistant properties of ceramic materials ensure durability, even in the face of harsh formulations, making our pumps a smart investment for manufacturers aiming to optimize long-term performance.

Designed for a Wide Range of Home Care Products Neoceram’s dosing solutions are ideal for filling and dispensing various household and hygiene products, including: Liquid detergents • Fabric softeners • Dishwashing liquids • Surface cleaners • Disinfectants • Air fresheners • Stain removers • Hand sanitizers

Click each section to view related components. Each entry is a direct link to product details

COMPONENTS

DOSING SYSTEMS

High-Purity Ceramic Dosing Systems for Demanding Home Care Applications

NO CONTAMINATION RISK

High-purity ceramics ensure compatibility with even the most aggressive cleaning agents.

SUPERIOR CHEMICAL RESISTANCE

Prevents corrosion and material degradation, ensuring long-term reliability.

NO SEALS OR LUBRICANTS REQUIRED

Eliminates potential leaks and reduces maintenance costs.

PRECISION DOSING TECHNOLOGY

Guarantees accurate and consistent filling for both low- and high-viscosity liquids.

EXTENDED SERVICE LIFE

Durable monolithic ceramic construction withstands harsh production environments.

ACCURATE, HIGH-SPEED DISPENSING WITH CORROSION RESISTANCE AND DURABILITY FOR AGGRESSIVE CHEMICALS

OTHER INDUSTRIES

In addition to our specialized offerings for our main industries, our ceramic piston pumps bring durability and reliability to a wide range of other sectors.

From chemical processing to industrial manufacturing, our solutions offer resistance to wear and aggressive substances, extending the operational life of your equipment. The strength of ceramic materials makes them ideal for applications that involve abrasive particles, high pressures, or corrosive environments. Neoceram’s dosing systems are designed to handle diverse industrial formulations, making them ideal for applications such as:

- High-viscosity and UV-curable inks

- Conductive pastes and battery electrolytes

- Industrial adhesives and sealants

- Precision dosing of lubricants and coolants

- Chemical and solvent-based formulations

- Paints and coatings requiring exact consistency

- Abrasive suspensions and slurrie

Whatever the industry, our pumps deliver consistent performance and minimize maintenance needs, helping you optimize your production processes.

Click each section to view related components. Each entry is a direct link to product details

ENGINEERED FOR PRECISION: Neoceram Ceramic Systems for Industrial Dosing

UNCOMPROMISED MATERIAL PURITY

High-density ceramic components prevent contamination and ensure process stability.

SUPERIOR CHEMICAL AND WEAR RESISTANCE

Withstands aggressive solvents, corrosive substances, and abrasive materials.

SEAL-LESS AND LUBRICANT-FREE DESIGN

Minimizes maintenance and eliminates the risk of leaks or product degradation.

HIGH-PRECISION VOLUMETRIC DOSING

Ensures accurate dispensing, reducing waste and improving process efficiency.

EXCEPTIONAL DURABILITY

Monolithic ceramic construction provides long-lasting performance even in extreme operating conditions.

SOLUTIONS IN RESPONSE TO THE SPECIFIC NEEDS OF SPECIAL APPLICATIONS