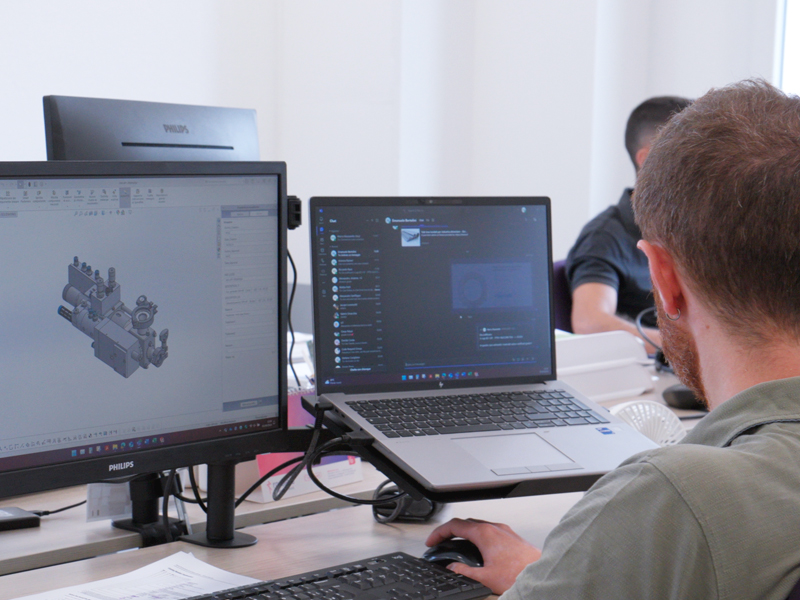

To perform every day, our engineering team uses the most up to date engineering systems available in the market (DAO, FAO, PLM, ERP). With these tools, we propose reliable solutions for both our internal and external customers.

To maintain a high quality of design, our engineers and draughtsmen follow a programme of Continuous Professional Development with ongoing training. New rules and regulations are continuously studied (3A, EHEDG) to maintain up to date designs. We also follow the latest progress in machining technology and take this into account to achieve better engineering solutions.

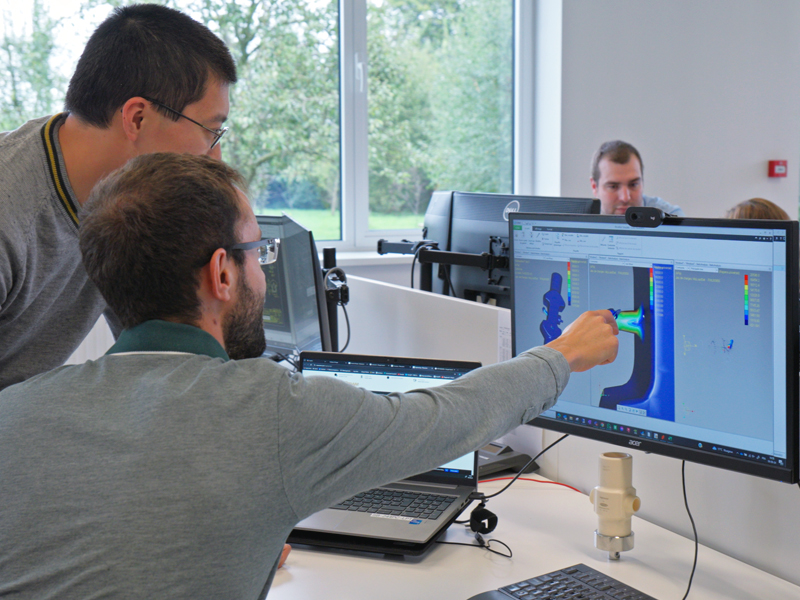

Located in two sites our engineering team is multi-cultural. It creates a competitive advantage by open mindedly sharing knowledge and experiences.

The definition of the design is made in close collaboration with our customers. It can be as simple as the minor customisation of an existing pump, a revamping or a full project starting from a blank sheet. This is why the most important characteristics of our team are innovation, a creative mind and rigor. (Neoceram filed 2 patents in the last 3 years). With daily technical discussions the Neoceram R&D team work with the client to reach the best possible solution.

The R&D team actually manages the machining of the prototypes. With the manufacturing team, it defines the best procedures to optimise quality and cost. It defines also the industrialisation steps necessary to obtain the best delivery time and market price.

Our multilingual after sales team helps our customers deal with trouble shooting, provision of spare parts and repairs. The team aims for a fast and customised answer to any question the customer may have.

We create top-performing precision instruments from powder to product, from project to solution.